|  ModBargains is proud to offer you the BRAND NEW FORGESTAR Wheel Lineup with the latest technology in wheel production to bring you the best of both worlds. This brand new lineup utilizes a combination of the best methods of forging and casting methods both in the same wheel. This is called Flow Form Casting, and is used by companies such as BBS and Enkei. These wheels are made to order and can be made to fit your Porsche with a large range of offsets. ModBargains is proud to offer you the BRAND NEW FORGESTAR Wheel Lineup with the latest technology in wheel production to bring you the best of both worlds. This brand new lineup utilizes a combination of the best methods of forging and casting methods both in the same wheel. This is called Flow Form Casting, and is used by companies such as BBS and Enkei. These wheels are made to order and can be made to fit your Porsche with a large range of offsets.

Flow Form Casting is a production procedure that turns the wheel (or rim section) over a special mandrel and three hydraulic rollers using tremendous pressure. The pressure and turning then force the rim area to form against the mandrel, creating the shape and width of the rim. During Flow Forming, the rim actually ""flows"" down to create the full rim width. During Flow Forming, pressure applied to the cast rim actually changes its mechanical properties, so its strength and impact values become similar to those of a forged rim. That translates to up to 15% less weight when compared to a standard cast wheel.

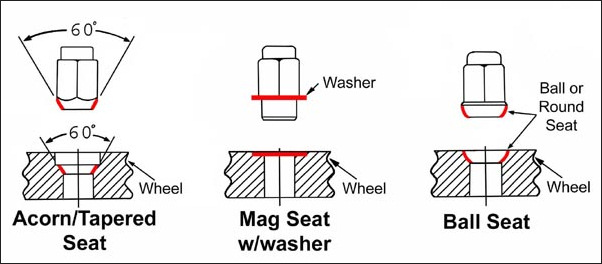

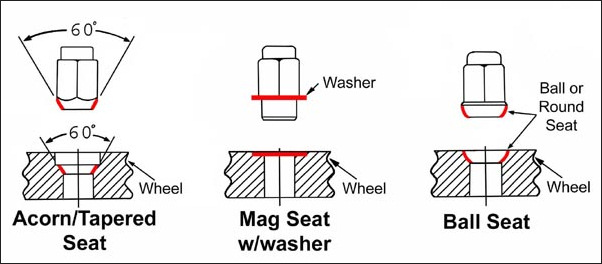

Please note the Forgestar F14 will require cone seat lug bolts so that the wheels sit properly on the hub. We can provide these for you (see attributes). |

|

CLICK THIS PICTURE TO GO TO THE FORGESTAR F14 PHOTO GALLERY! Features: - High Quality flow form production

- Durability of a Forged Wheel

- Lightweight and Excellent Value

- TPMS Compatible

- Clears OEM calipers and aftermarket big brake kits

- Custom offsetsand bolt patterns

- Fits nearly any vehicle!

- Wheels are made to order

Forgestar F14 Available Finishes

All Forgestar F14 finishes are now powdercoated. If you would like a custom pinstripe please call in to place your order, (714) 582-3330. - Gloss Black

- Matte Black

- Textured Black

- Silver

- Gunmetal

- Textured Gunmetal

- Frost White

- Race Gold

- Premium custom powdercoat finishes also available (See below)

- Semi Gloss Black

- Brushed Black

- Brushed Charcoal

- Brushed Titanium

- Carbon Overlay - 100% real carbon fiber overlay

- Karbon Overlay- This is a carbon fiber look overlay

Custom Finishes Available:

Increased Load Ratings

The 18"" Forgestar F14 now has an increased load rating per wheel. The JWL VIA certified load rating for all 18"" F14 sizes is 1520Lbs, up from 1200Lbs per wheel.

Available Offsets and Sizes - 18x8.5 offsets from +26 to +50

- 18x9.0 offsets from +20 to +55

- 18x9.5 offsets from +26 to +60

- 18x10.0 offsets from +16 to +42

- 18x11.0 offsets from +23 to +55

- 18x12.0 offsets from +36 to +68

| | Why Forgestar Wheels are Better Than Cast Wheels - Custom Offsets - Forgestar wheels can be made in virtually any offset, whereas standard cast wheels come in a set offset. This allows you to dial in exactly how you want your wheels to sit (we can help you select the offset you need for the look your looking for). Having custom offsets allows for fitment of wider wheels in stock suspension and lowered vehicles. Forgestar wheels are designed specifically for your car and it's suspension setup, where cast wheels are designed for everyone and typically do not take in to account lowered suspension setups.

- Weight - Forgestar wheels are also much lighter than cast wheels. The 18x8.5 F14 wheel weighs an amazingly light 18.5 lbs, where a cast wheel of this same size would weigh anywhere from 23-27 lbs. This saving of roughly 6-10 pounds per wheel makes a BIG difference in regards to handling and drivability. Reducing unsprung weight (weight that is not supported by the car's suspension, i.e wheels, tires, brake rotors, and brake calipers) is one of the easiest ways to improve your car's handling, braking, and acceleration. As a general estimate 1 pound of unsprung weight is equal to 10 pounds of static weight. (weight that is supported by the vehicle's suspension). By using this ratio if you were to replace your stock wheels that weighed 25 lbs with Forgestar wheels you would be saving 320 lbs. in static weight!

- Strength - Flow-formed wheels are similar in strength to that of a fully forged wheel, without the cost. The process used to make the Forgestar wheels is the same process BBS wheels uses as well. Forgestar wheels are also rated at 1520 lbs per wheel which is considerably more than a cast wheels which are typically around 1000-1200 lbs. per wheel.

- Range of Sizes - Forgestar wheels are available in a multitude of sizes, allowing you to decide exactly what diameter and width you want to run on your vehicle, rather being forced to run a set staggered size with cast wheels (As cast wheels usually are only available with one set front wheel width, and one rear wheel width).

Weights -

18x8.5 ET48 - 18.5 Lbs. -

18x9.5 ET48 - 20.1 Lbs. -

18x10 ET42 - 19.4 Lbs. -

18x12 ET68 - 21.5 Lbs. Shipping

Local pickup of these wheels can be performed in the southern California area, please e-mail a ModBargains sales representative to schedule an appointment. Otherwise shipping is a flat $99 to the US. International shipping quotes are available via email. |

Forgestar F14 Wheel Finishes:

Forgestar F14 Gunmetal:

F14 Gunmetal 19x8.5 ET48 / 19x10 ET33

F14 Gunmetal 19x8.5 ET48 / 19x10 ET33

F14 Gunmetal 19x8.5 ET48 / 19x10 ET33

F14 Gunmetal 19x8.5 ET48 / 19x10 ET33

F14 Gunmetal 19x8.5 ET48 / 19x10 ET33

F14 Gunmetal 19x8.5 ET48 / 19x10 ET33

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8 / 19x10

F14 Gunmetal 19x8 / 19x10

F14 Gunmetal 19x8.5 / 19x10

F14 Gunmetal 19x8.5 / 19x11

F14 Gunmetal 19x8.5 / 19x11

F14 Gunmetal 19x8.5 / 19x11

F14 Gunmetal 19x8.5 / 19x11

F14 Gunmetal 19x8.5 / 19x11

F14 Gunmetal 19x8.5 / 19x11

F14 Gunmetal 19x8.5 / 19x11

F14 Gunmetal 19x8.5 / 19x11

Gloss Black:

Forgestar F14 on Porsche 996 Twin Turbo Gloss Black

Front: 19x8.5 Rear: 19x11

Forgestar F14 on Porsche 996 Twin Turbo Gloss Black

Front: 19x8.5 Rear: 19x11

Forgestar F14 on Porsche 996 Twin Turbo Gloss Black

Front: 19x8.5 Rear: 19x11

Semi Gloss Black:

Forgestar F14 in Semi-Gloss Black on Porsche 996 Turbo

Front: 19x8.5 Rear: 19x11

Forgestar F14 in Semi-Gloss Black on Porsche 996 Turbo

Front: 19x8.5 Rear: 19x11

Forgestar F14 in Semi-Gloss Black on Porsche 996 Turbo

Front: 19x8.5 Rear: 19x11

Forgestar F14 in Semi-Gloss Black on Porsche 996 Turbo

Front: 19x8.5 Rear: 19x11

Matte Black:

Matte Black Forgestar F14 on Porsche 997 Carrera S

Front: 19x8.5 Rear: 19x11

Matte Black Forgestar F14 on Porsche 997 Carrera S

Front: 19x8.5 Rear: 19x11

Silver:

Forgestar F14 Brushed Titanium

Forgestar F14 in Brushed Titanium on Porsche 997 at the Track

Front: 19x9.0

Rear: 19x11

Blood Red:

Anodized Purple:

Tiffany Blue:

Bronze Burst:

F14 Bronze Burst 19x8.5 / 19x11

F14 Bronze Burst 19x8.5 / 19x11

Textured Bronze:

Forgestar F14 Textured Bronze 18x8.5 / 18x11 on Porsche 997 Carrera 2

Forgestar F14 Textured Bronze 18x8.5 / 18x11 on Porsche 997 Carrera 2

Forgestar F14 Sunken Treasure (CUSTOM)

Forgestar F14 Sunken Treasure (CUSTOM) 19x9 / 19x11

Race Gold

Forgestar F14 Race Gold Porsche 997 Carrera 4S 20x8.5 / 20x12

Forgestar F14 Race Gold Porsche 997 Carrera 4S 20x8.5 / 20x12

Forgestar F14 Race Gold Porsche 997 Carrera 4S 20x8.5 / 20x12

Forgestar F14 Race Gold Porsche 997 Carrera 4S 20x8.5 / 20x12

Forgestar F14 Race Gold Porsche 997 Carrera 4S 20x8.5 / 20x12

Forgestar F14 Race Gold Porsche 997 Carrera 4S 20x8.5 / 20x12

Matte Antique Bronze (CUSTOM FINISH)

Matte Antique Bronze 18x9 / 18x12

What you need to know about the Flow-Forming Procedure

| Forgestar's flowforming process is a unique solution to a common problem – how to make a wheel both light and strong.

|

| This specialized process begins with a low pressure type of casting and uses a special machine that spins the initial casting, heats the outer portion of the casting and then uses steel rollers pressed against the rim area to pull the rim to its final width and shape. The combination of the heat, pressure and spinning create a rim area with the strength similar to a forged wheel. During Flow Forming, the pressure applied to the cast rim actually changes its mechanical properties, so its strength and impact values become similar to those of a forged rim. That translates to up to 15% less weight when compared to a standard cast wheel. The resulting grain structure within the alloy of the wheel is linear, flowing in a single direction.

This grain structure pattern, combined with the exceptional quality of casting required for the process, gives the rim area of the wheel huge mechanical strength, and elongation. As a result of these mechanical characteristics, Forgestar is able to reduce the thickness of the rim area resulting in reduced weight, without compromising strength and resistance to impact. So in a nutshell, the process makes the wheels: -

Almost as strong as forged wheels -

Lighter than cast wheels -

Customizable to a range of offsets and bolt patterns -

A great value for the price |  |

|

Pictures of the Flow-Forming Process:

| Forgestar has long been an advocate for wheel durability testing. They strongly believe that any issue regarding consumer safety is an important one. They want every customer contemplating the purchase of Forgestar wheels to know that it has been carefully engineered by the Forgestar team and thoroughly tested by independent third-party testing laboratories. Actual test reports from independent third-party test laboratories, such as Standards Testing Labs (STL), have been provided by Forgestar. The most common test standards used are those published by SAE (J2530) and TUEV Rheinland (Germany). PDF files of these actual test reports are provided below as well as an explanation of how the tests are performed and what the results mean to you as a consumer. They send every width in each wheel design family with the offset configuration that presents the greatest testing challenge and subject it to the equivalent of a full product lifetime of stress in a third-party laboratory. In this way, it is ensured that the recommended wheel fitment is safe at maximum rated load. |

| FO5 WHEEL TEST DATA STL REPORT 19x8.5 (PDF 35K)

STL REPORT 19x9.0 (PDF 35K)

STL REPORT 19x10 (PDF 35K) | F14 WHEEL TEST DATA STL REPORT 19x8.5 (PDF 35K)

STL REPORT 19x9.0 (PDF 35K)

STL REPORT 19x10 (PDF 35K)

STL REPORT 19x11 (PDF 35K) |

The Forgestar Wheels will come with a set of carbon fiber center caps. Below are pictures of these.

Carbon Fiber Center Cap

Not sure what Forgestar F14 finish will look best with your Porsche? Call us at 714-582-3330